FAST Sintering or Field Assisted Sintering Technology

FAST Sintering or Field Assisted Sintering Technology

FAST Sintering : a new process, more efficient than traditional sintering

FAST Sintering (or Field Assisted Sintering Technology), is a process that allows the production of more resistant and high-density materials from powders.

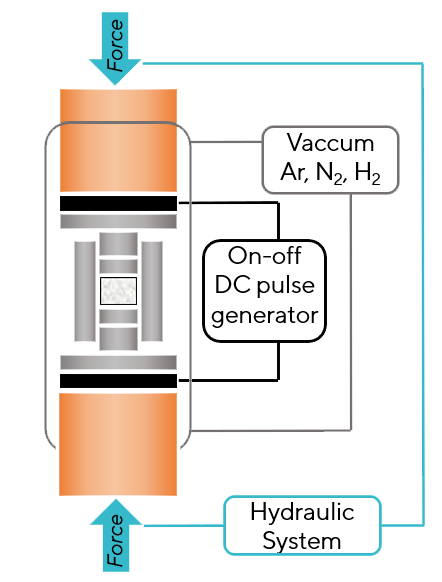

It’s a sintering method that uses pulsed DC (direct current) and uniaxial pressure to provide a quick heating and a high rate of consolidation.

This manufacturing process is also known as Pulsed Electrical Current Sintering (PECS) or Spark Plasma Sintering (SPS).

Here are the main production stages:

- Powders are placed in a mold (usually made of graphite) between two electrodes,

- A pulsed DC (PDC or pulsed direct current) is applied and runs through the material, producing an electric field with a plasma effect,

- This plasma effect creates intense local heat, which quickly heats the powder,

- Meanwhile, uniaxial pressure is applied, helping to consolidate the material.

High-value benefits of FAST Sintering for the industry

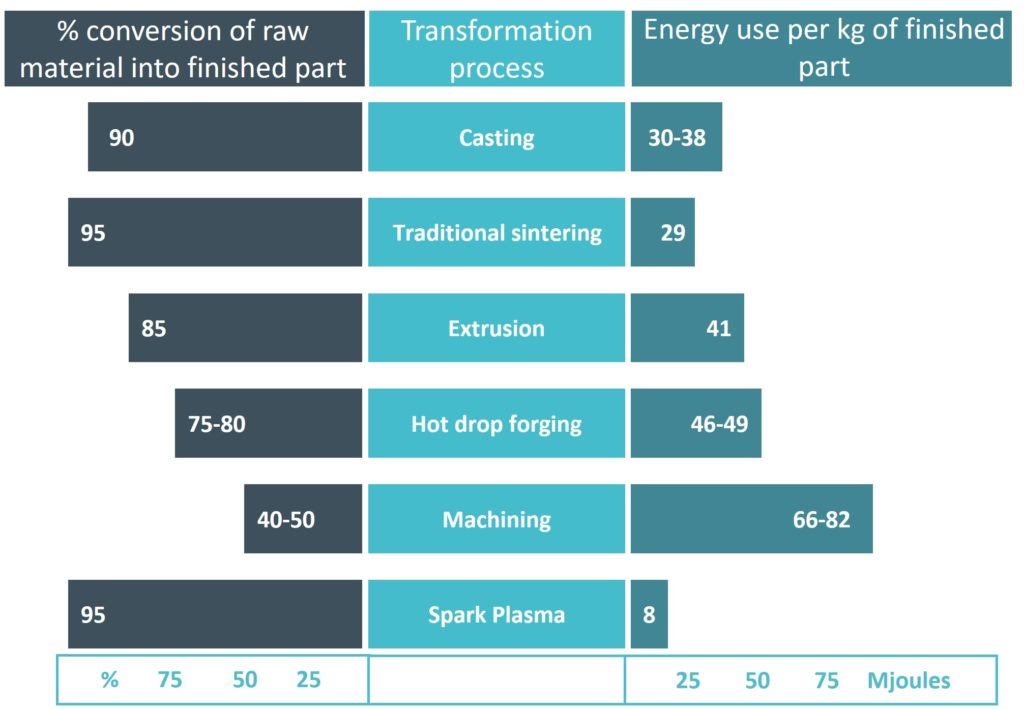

FAST Sintering or PECS offers several advantages over traditional sintering techniques. For example, it enables production of high-density materials with lower energy consumption and shorter production cycles.

It can also maintain the material's nanostructure, which is useful for certain specific applications.

Moreover, it can be used with a wide range of materials, including ceramics, metals, and composites.

The main benefits of this technology are as follows :

- Improved technical characteristics,

- Quick production cycle,

- Assembly of materials without the addition of additives,

- Use of varied materials, industrial or bio-sourced,

- Reduced energy consumption.

Sintermat industrializes Field Assisted Sintering Technology

Sintermat is one of the few specialists in the industrialization of this innovative technology.

Through FAST Sintering, we produce parts for industries such as aeronautics, luxury, industrial tools, defense, and energy.

Our company can, for example, manufacture metal/ceramic composites – Cermet -, tungsten carbide parts without binder, or parts based on bio-sourced materials.

Have you got a project ?

Do you want to offer innovative products and unique materials to your customers ? Would you like to improve your parts ? Do you wish you could recycle your production scrap ? Contact us today.