Eco-materials

Eco-materials

Building a more sustainable industry together

What if we could align industry and environment?

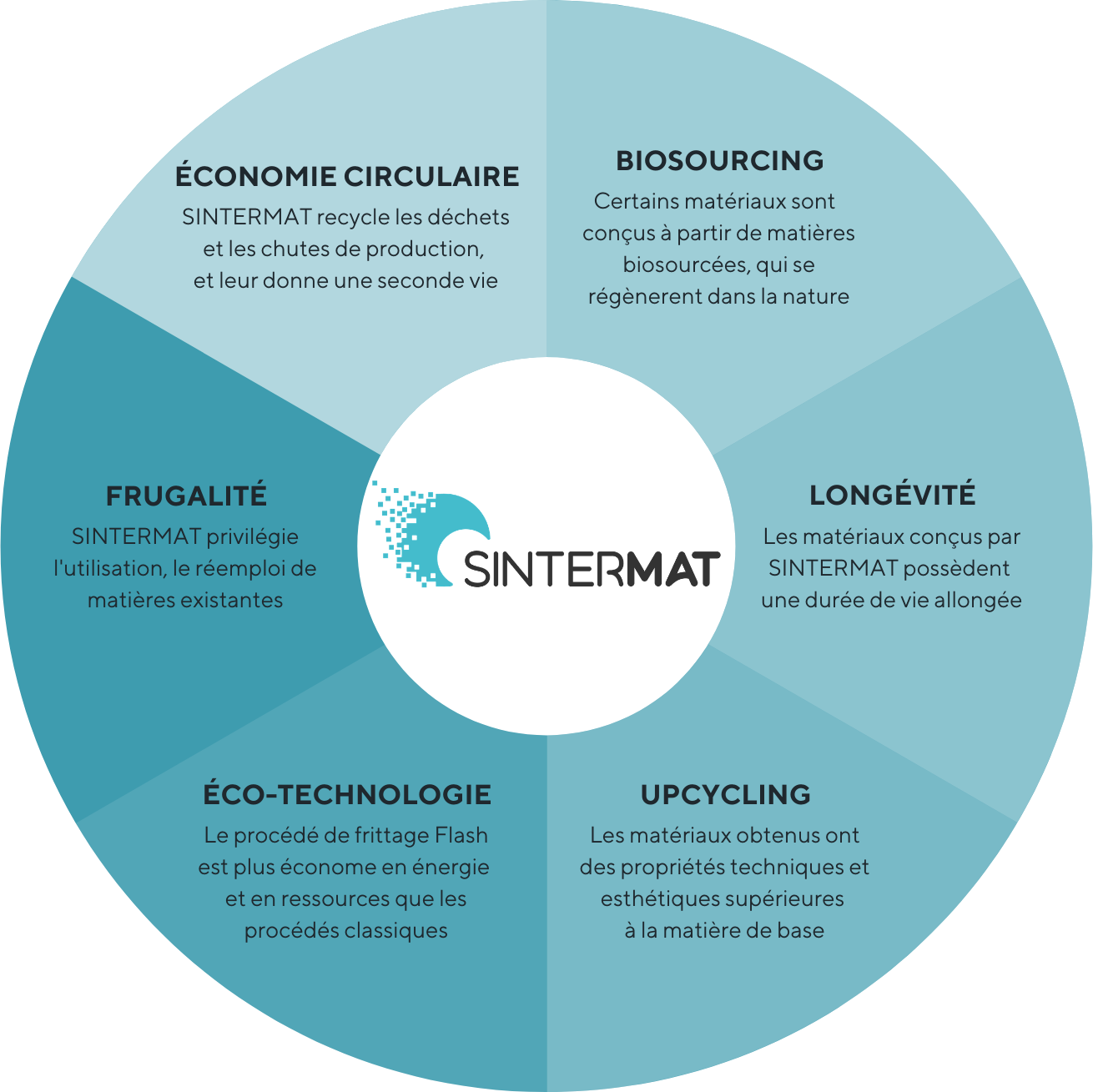

Sustainable development is not just a trend or mere concern, it is built into SINTERMAT’s very DNA.

Our primary mission is to be involved in a greener industry by developing the production of new parts using industrial or bio-based materials, thereby reducing the quantity of raw materials required for production.

By recycling materials and upcycling waste, we are subscribing to a circular economy approach, providing sustainable solutions to manufacturers in order to reduce their environmental impact.

We find solutions to your problems:

- Recycling industrial waste

- Recycling production scrap, unsold goods, surplus, quality shortfalls, etc.

- Producing “greener”

- Proposing eco-designed products

- Proposing recycled and recyclable products

A serious situation

Numerous economic, social and environmental challenges

- Depletion of natural resources

- The extraction, use and sale of energy-consuming and polluting metals

- The imminent shortage of certain metals

- Dependence on raw material imports

- Plastics—the scourge of the oceans and their biodiversity

- The export of millions of tons of waste every year

It is time to reduce the consumption of raw materials and set up a circular economy for more eco-friendly materials.

Eco-friendly technology and materials

When the material returns to its material state...

By proposing disruptive innovation in the area of augmented materials, we hope to reinvent production means. We have integrated environmental concerns into all the stages of our products’ life cycle: raw materials, manufacture, transport, use and end of life.

We are proposing eco-designed materials created using eco-technology based on sintering

Green

SINTERMAT offers an eco-friendly solution. Raw material imports and wasted natural resources are reduced. The manufacturing process is environmentally-friendly. The service life and use of the products are extended. The materials are recyclable in an infinite virtuous cycle. They have a positive impact on the environment; for example, by offering lightweight parts for aviation, we are contributing to a greener aeronautical industry.

Eco-designed

The materials produced by SINTERMAT are eco-designed. They are made from bio-based materials (wood, leather, horn, husk, coffee grounds, oyster shells, snail shells, fish scales, etc.). The products integrate the environmental concerns at all stages of the life cycle: raw materials, manufacture, transport, use and end of life.

Recycling

Materials designed by SINTERMAT may be recycled ad infinitum, thereby becoming part of a circular economy and greener industry. Thanks to recycling, there are fewer power-hungry and environmentally-harmful material production stages (extraction of the raw materials, first stages of processing). There is also a reduced need for raw materials, which cuts down imports and dependence on other countries. SINTERMAT avoids the end-of-life disposal of products, thereby reducing the export of waste.

Eco-technology

SINTERMAT uses an eco-innovative process. The manufacturing process is low on energy-consumption (under 20% to 30% compared with hot isostatic and hot-pressing sintering processes). Production time is very short. Heating and cooling are controlled through the use of high-tech tools. No additives or binders are required. Over 90% of the material is used in the process. There are fewer production stages thanks to the Near Net Shape (very close to the final dimensions) or even Net Shape (exact dimensions) manufacturing process.

Upcycling

The value of the materials obtained by SINTERMAT is superior to the initial resource (improved performance, etc.).

Biomimicry

SINTERMAT takes inspiration from shapes and colors present in nature when designing its products.

Bio-based

SINTERMAT uses bio-based materials (plants, wood, oyster shells, etc.) to create new materials.

We are bold and demanding in our desire to align the economic challenges of augmented material production

with social and environmental challenges

Have you got a project?

Do you want to offer innovative products and unique materials to your customers? Would you like to improve your parts? Do you wish you could recycle your production scrap? Contact us today.