Devising and creating the materials of tomorrow

SINTERMAT is a start-up specializing in the design of innovative materials

In 2016, after about a decade of research in the laboratories of the University of Burgundy and as a result of growing industry demand, researcher Foad Naimi created SINTERMAT.

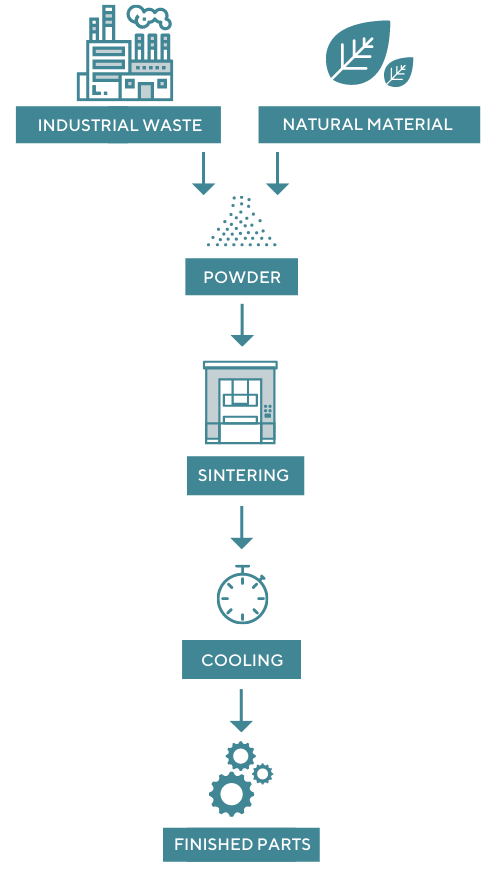

SINTERMAT is industrializing an innovative powder metallurgy process known as flash sintering (or SPS). This process enables the design of augmented materials using metal, composite and natural powders that offer multiple applications in the aeronautical, defense, industrial, luxury goods, energy and health sectors, among others.

These augmented materials are graced with unprecedented properties and exceptional performances: high strength, high-density, increased hardness, extended service life, light weight, unique design and more.

Our aim is to align industry and environment. Our technology and products contribute to a greener industry and circular economy by recycling material and upcycling waste.

SINTERMAT has a machinery stock and expertise that are unique in Europe. We are supported by many public (Armed Forces Ministry, Bpifrance, etc.) and private organizations.

As a rapidly expanding company, we are constantly innovating and bringing new solutions to industries—present and future.