Offer

Offer

A new era of augmented materials

SINTERMAT develops innovative solutions for these 3 product types: wear parts, structural parts and distinctive creative parts.

Wear parts

SINTERMAT designs wear parts with an extended service life. In some cases, the process is simplified with a reduced number of stages in comparison to conventional technologies. Example use: extrusion sectors (industrial tooling)

Structural parts

SINTERMAT designs structural parts with improved performances: longer service life, better mechanical characteristics, lighter weight, superior energy efficiency, etc. Example use: airplane turbines (aeronautical industry)

Distinctive creative parts

SINTERMAT designs unique parts of sophisticated design and offers a collection of patented materials and short-term exclusivity. Example use: watch bezels and cases (luxury goods industry)

SINTERMAT, an expert in high-performance materials

SINTERMAT proposes augmented material solutions (lighter weight, improved mechanical strength under extreme conditions, increased corrosion resistance, etc.).

Our clients hail from a variety of backgrounds: from SMEs to major accounts. Located in France and abroad, they operate in multiple sectors: aeronautics, security/defense, industry, energy, luxury goods, etc.

We sinter/assemble:

- Light-weight materials (light alloys)

- Ultra-hard materials

- Controlled porosity materials

- Metal and ceramic materials

- Composite materials

- Innovative materials

- Natural materials

A dual offer

Materials with high-tech requirements

SINTERMAT devises solutions based on industrial materials: pure metals, metal alloys, ceramics, polymers, composites, thermosetting materials, etc.

Examples: steel, stainless steel, alumina, zirconia, nickel-based alloys, silicon nitride, gold, palladium, PET, etc.

Natural materials

SINTERMAT devises solutions based on recycled and natural materials.

Examples: vine shoots, brewers’ grains, fish scales, salt, algae, sunflower, husks, leather, horn, juniper wood, oyster shells, cork, etc.

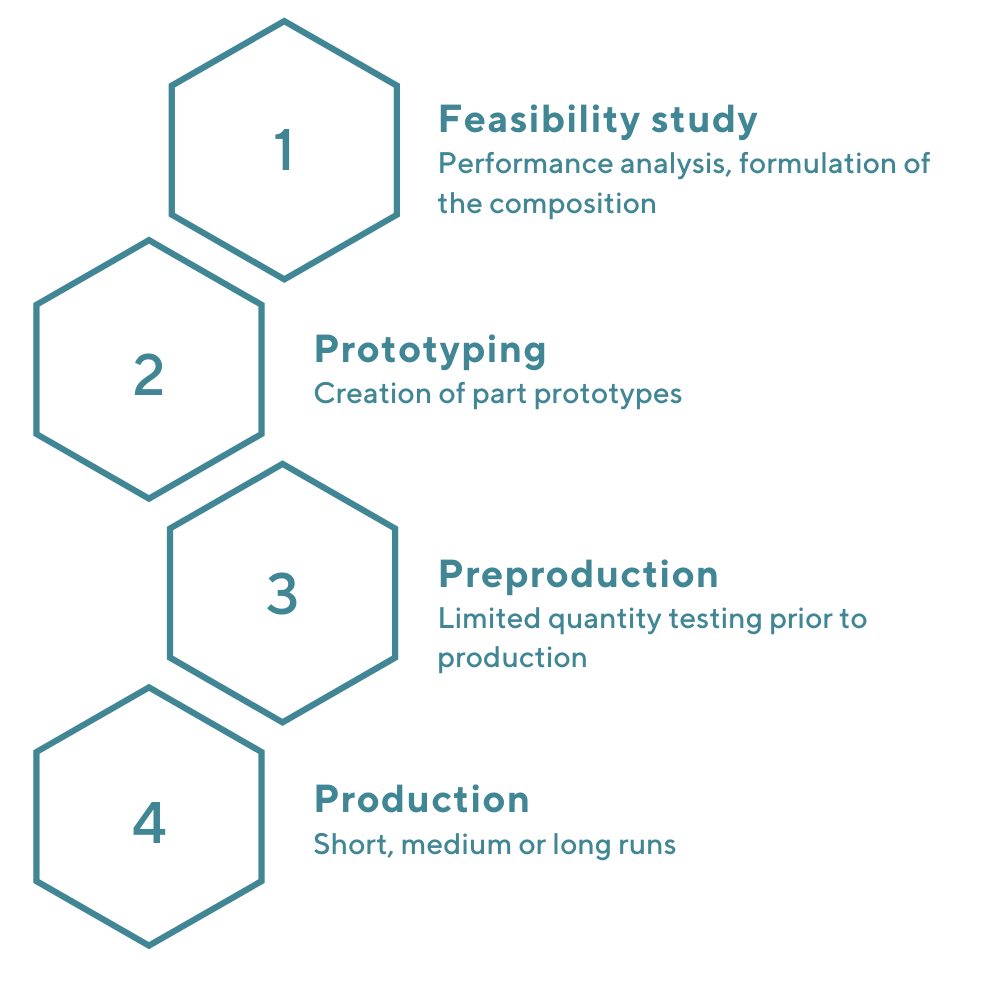

Customized support

SINTERMAT offers a comprehensive service from approving the specifications through to prototyping and production of parts.

SINTERMAT has an in-house design office to test and design your products.

10 reasons to choose SINTERMAT

- Sintering technology expertise with a wide variety of materials (including bio-based)

- Recognized and patented know-how

- Eco-responsible technology and product

- The most highly developed multi-technology and SPS machine stock in Europe

- A “Made in France” product and production system

- Customized solutions adapted to suit your needs

- Short, medium and long production runs

- The production of complex Near Net Shape parts

- Shorter production times

- Competitive pricing

Have you got a project?

Do you want to offer innovative products and unique materials to your customers? Would you like to improve your parts? Do you wish you could recycle your production scrap? Contact us today.