Aviation

Aviation

High-performance materials adapted to the aeronautical industry

High-performance metal and ceramic materials

The aeronautical industry is currently facing numerous challenges: it must stand out from strong international competition, produce more and at lower cost, reduce maintenance costs, propose new innovations, reduce CO2 emissions from airplanes, etc.

SINTERMAT is helping the aeronautical industry meet these various challenges by proposing higher performance components that are adapted to the strict requirements of the sector.

We offer the aeronautical industry:

- Parts with improved mechanical properties (thrust, creep)

- Stronger parts

- Lighter parts

- Parts that have better corrosion resistance

- Parts with extended service lives

Innovative materials

Augmented materials with controlled performances

Thanks to our process, our materials are ultra-high performance and have totally original technical characteristics: better corrosion resistance, improved mechanical properties, extended life span, lighter weight, etc.

An extremely quick production cycle

The flash sintering/SPS method is easy and quick to implement—some parts can be produced in less than an hour. There are fewer production stages (pre-compaction, compaction and cooling). The machining stage may even be completely avoided in some cases.

Customized design

We can combine several materials without the need for additives, resulting in multi-materials. The multiple customization options (shade, material, texture, etc.) offer limitless creativity.

An eco-friendly solution

Our process works using industrial materials (metal, ceramics, etc.) as well as bio-based materials (wood, plants, etc.). Manufacturing is environmentally-friendly: fewer stages, less raw material waste, controlled heating and cooling, consumption of the material kept to a bare minimum thanks to Near Net Shape or even Net Shape production.

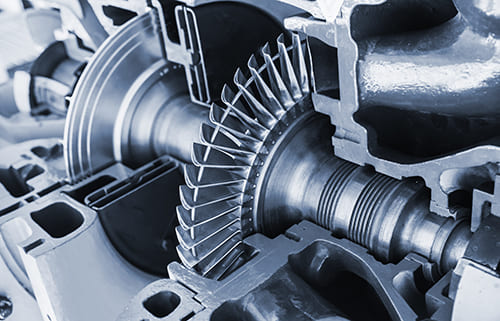

Client cases: Parts for airplane turbines

- The production feasibility using this innovative process has been proven

- The quality of the material obtained is equivalent or even better than the quality commonly obtained through foundry and/or forge processes

- The production cycle time is shorter

- The reduced energy consumption relating to the use of this process is significant

In brief, the potential for improved production of existing parts has been proven.

Have you got a project?

Do you want to offer innovative products and unique materials to your customers? Would you like to improve your parts? Do you wish you could recycle your production scrap? Contact us today.